BARN DESIGN AND ANIMAL FLOW

Electronic Sow Feeding

BARN DESIGN AND ANIMAL FLOW

Highlights

- The AP/Schauer Team has experience with a variety of pen housing options from total-slatted confinement barns, to partially-slatted sow barns, to deep bedded barns.

- Our expert team will provide concept designs for your ESF initiatives that include recommendations to help minimize the untoward effects of social hierarchy in group housing.

- We will help identify the best combination of animal flow and grouping strategies that promise maximum productivity.

- Over 100,000 sows are being fed by Compident ESF stations in AP Schauer-designed pen gestation barns across the U.S.

ESF Videos

Tennessee Producer Shares thoughts on Electronic Sow Feeding

Watch as we take a walktrhough of the Electronic Sow Feeder (ESF) system at the Herrondale sow farm in Henry, Tennessee. Jim Maggart, Regional Production Supervisor of the Herrondale farm, shares his thoughts and experience with the AP ESF and post-implantation design.

Rail Heading

Tennessee Producer Shares thoughts on Electronic Sow Feeding

Watch as we take a walktrhough of the Electronic Sow Feeder (ESF) system at the Herrondale sow farm in Henry, Tennessee. Jim Maggart, Regional Production Supervisor of the Herrondale farm, shares his thoughts and experience with the AP ESF and post-implantation design.

How We are Using the Electronic Sow Feeder

Dennis and Tara Terpstra operate a 370 sow farrow-to-finish farm near Brussels, Ontario. Listen as they share their experience with loose housing and the AP Electronic Sow Feeding system.

Electronic Sow Feeding – Maximum Animal Health, Maximum Productivity

Healthy pigs are productive pigs. AP’s Electronic Sow Feeder ensures each sow gets her share of feed for the day, safely and individually in the stall.

Electronic Sow Fedding – Flexible, Efficient Design

An overview on the flexible design of Electronic Sow Feeder (ESF). The ESF can be set up to fit the needs of any group sow housing operation.

Why I Use an Electronic Sow Feeding System

Listen while Automated Production Systems visits with a customer and AP representative Jeff Schoening about how thy are using electronic sow feeding in their operation.

Electronic Sow Feeding – Painless Setup, Easy Maintenance

AP’s Electronic Sow Feeding (ESF) System can be set up to fit any operation. ESF is simple to set up and service, and creates an environment that is safe and healthy for your pigs.

Built to Perform

Layout Options

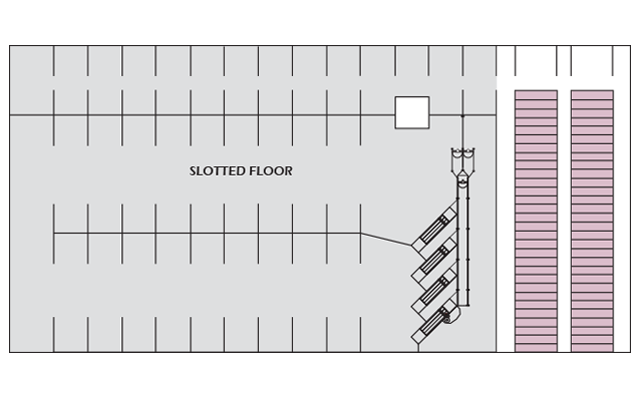

Typical Post-Implantation Layout with Static Groups

Group is constituted once, social hierarchy stabilizes, and the group is left intact for the duration of gestation. The goal is to have one weeks breeding (or a fraction of that weeks breeding) in a larger sow unit to be used to constitute a static group. The advantage of this approach is that the breeding group stays physically intact much as it would in a crated facility. However, static groups can create challenges in space utilization, resulting in increased facility cost or decreased sow inventory. Static groups are an “all in / all out” system that requires additional barn spaces in reserve to allow for animal movement. In reality, very few gestation groups are truly static as some sows will drop out due to pregnancy loss, injury or death. This leads to suboptimal utilization of pen space by the end of the gestation period because sows removed from the group cannot be replaced. Alternatively, one can attempt to anticipate this fall-out by overstocking the pen initially which can result in a less than ideal per sow space allotment.

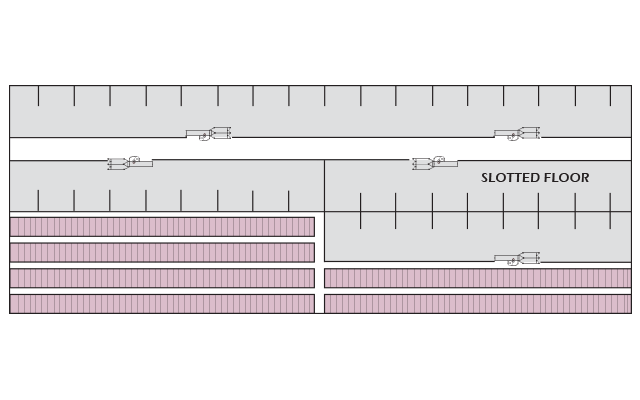

Typical Pre-Implantation Layout with Large Dynamic Groups

Group constituency is constantly changing. Dynamic groups are essentially a “continuous flow” system which allows space utilization to be optimized in each pen. Weekly breeding groups are subdivided with animals being introduced into a number of different pens optimizing the space utilization in each pen. This approach works well with large group sizes and can also be used to optimize feed station utilization in sow units with smaller breeding groups. Social disruption and associated fighting is minimal in large groups and any repeat breeders can simply be re-bred and left in the same pen. It is not necessary to maintain the integrity of the breeding group because the computer system will track the location and monitor the status of animals regardless of their location. The feeding station can be used to sort or mark the sows for scheduled management activities as a group regardless of in which pen the sows are located. The flexibility in animal movement and the ability to achieve optimum space utilization in all pens makes dynamic groups an attractive solution for many herds.