Today’s sow feeders can address sow nutrition based on each individual animal’s needs. Using an RFID tag, the feeder can recognize which sow is in the feeder and can provide for her specific nutritional requirements. Some systems can provide a specific amount of feed, while others can also top dress with nutrients or add specific rations for energy and protein needs.

It’s all about keeping each sow in the proper body condition, a key part of keeping her - and her litter - healthy.

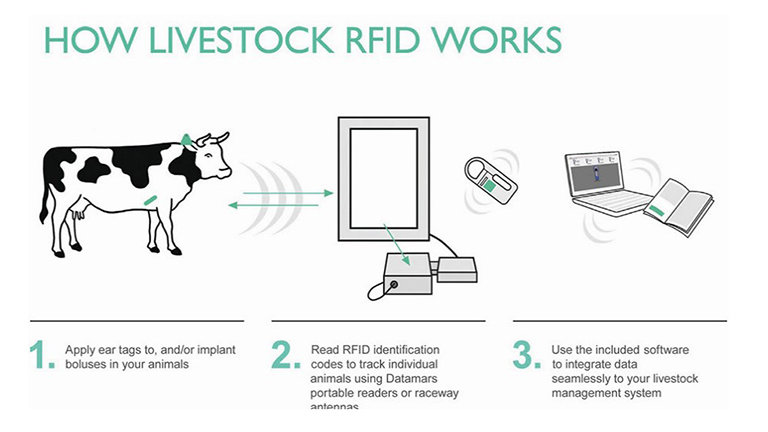

Something like this:

- Each sow is given a unique RFID tag

- Nutritional needs are calculated based on size, age, etc.

- The Gestation Sow Feeder (GSF) uses the tag to determine which rations and amounts are needed by the sow

- Sow is dispensed with the appropriate amount of the ration and any top dressing required to achieve her proper body condition