Housing and feeding sows have gone “full circle” in the past 50 to 60 years. Half a century ago, most sows were fed in a pen with multiple sows in each pen. The pork industry soon learned that housing in individual pens provided benefits for the sow. The caretaker could now feed each sow individually, they could administer vaccines with less chance of injury to the sow or the caretaker, and the animals were not exposed to other aggressive sows in the pen.

Recently, however, pressure by activists and consumers has affected the way we house and feed sows. Over the past 10 years, the industry has transitioned back to housing sows in groups rather than individual pens. So, what are the options to feed and manage sows in pens? We must remember that there have been many advances in technology since the mid-20th century. These advances include genetics, nutrition, feeding equipment and facility design. The level of technology used for feeding and housing equipment may be different for different production systems.

NAVIGATING PROPOSITION 12 IN YOUR SWINE OPERATION

Competitive and non-competitive designs

Generally, the types of sow housing and feeding designs are divided into two categories: competitive and non-competitive. These are exactly what the names imply. Competitive systems give sows the opportunity to compete for more feed, while non-competitive systems protect the sow and allow her to consume her share of feed.

Group housing and feeding in its simplest form is floor drop feeding. Producers have learned how to time the drop feeding, set up pen layout and position drop boxes to maximize the opportunity for each sow to consume her share of feed for that day. This is an example of competitive feeding. It is a low-cost option and uses very little technology.

Adding stanchions (or shoulder stalls) and individual drop feeders to a pen further increases the ability for each sow to consume her portion. This layout allows sows to guard their portion better and not have it stolen by other sows. While still a competitive system, technology is added to increase the chance for each sow to consume the proper nutrition needed for optimal performance.

Free access stall barns

Free access stall barns have an area which include individual stalls as well as a group area. Sows can let themselves out of or remain in the stall. Feed is delivered in the stall and sows are protected from other aggressive sows, which makes this a non-competitive system. While still fed as a group, each sow is able to eat her share of feed.

However, this system does not allow individual animal feeding as all of the sows in the pen will be fed the same portion. Supplementing a particular pig’s diet is possible, but requires more labor. Because this system requires more expensive equipment and square footage per sow, free access stalls are the most expensive group sow housing systems.

Electronic sow feeders

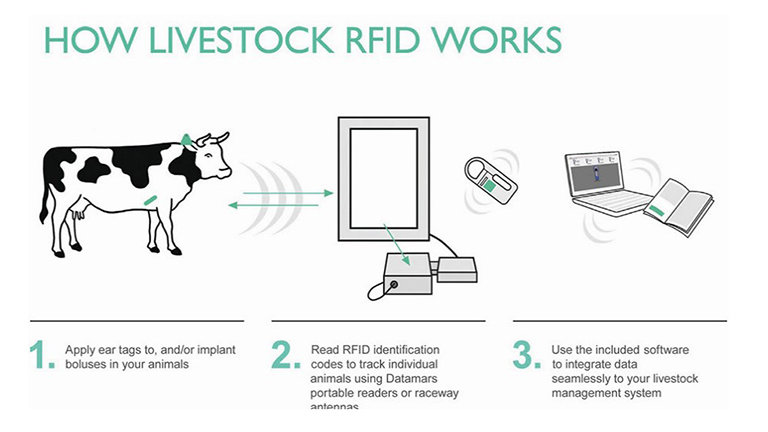

By modifying free access pens with a radio frequency reader and a mechanical feed dispenser, producers now have the capability to electronically feed each sow individually. This system is commonly referred to as a “walk in, back out” Electronic Sow Feeder (ESF).

Sows can be put on a feed curve and daily portions can automatically be adjusted over time. These walk in, back out feeder systems have fairly low maintenance requirements and are relatively easy to train sows to use. One feeder can feed 15 to 20 sows. This system is also non-competitive and an improvement in sow nutrition compared to previously discussed systems.

As a step up in technology, full-functioning ESF systems are also non-competitive and feed the sows individually. But typically, they have more electronics and may require slightly more sow and operator training. These systems allow animals to walk through the feeder instead of backing out. Water is also offered in a full-functioning ESF and up to 75 sows can be fed with one feeder.

Other advantages of full-functioning ESF systems include the ability to sort sows out of the pen if needed for treatments or to move to farrowing. As technology is developed for other management tasks, these operations will be easier and more cost effective to add to ESF. Two examples of this would be auto-pregnancy checking and auto-vaccination.

As more farms transition toward group housing, there are many options to consider and each system has its pros and cons. When making a sow housing and feeding system decision, producers should evaluate the ability of each system to feed sows properly and understand the management skillsets required of each system.

FEEDING YOUR SOWS IN PEN GESTATION

Jeff Schoening is technical sales manager for AP, an ACGO brand that manufactures feeding, watering, ventilation and biosecurity equipment for the swine industry. For additional information, visit www.automatedproduction.com.